The Golden Age System™

Smarter Homes, Built to Last

Golden Age homes combine timeless design with the latest in building technology. Our system is based on three key innovations: SIPs, our Engineered Modular Floor System, and our 4-Foot Grid Design Platform. Together, they make homes stronger, more energy efficient, and faster to build.

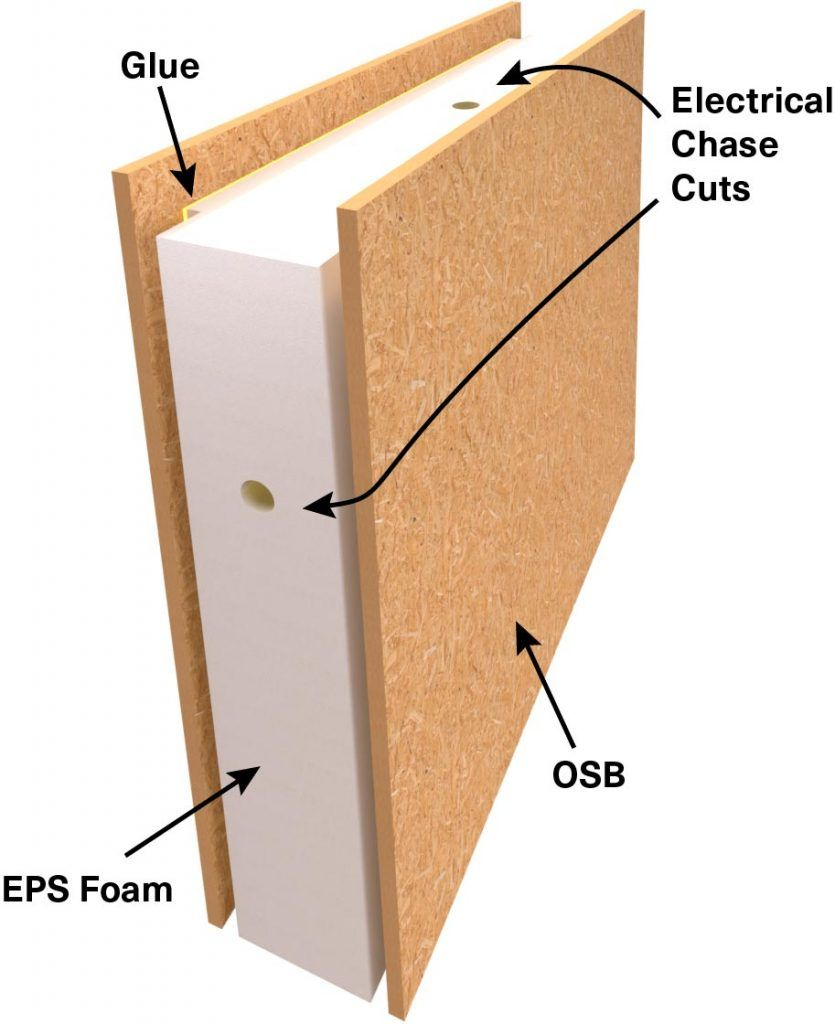

1. Anatomy of a SIP

Strength & Durability – Factory-pressed panels create a solid, structural wall and roof system capable of withstanding twice as much vertical uniform / point loads, and supporting up to three times as much sheer loads as traditional stick framing.

Continuous Insulation – Golden Age SIP homes only require structural studs every 8 to 16 feet, which means far less thermal bridging (heat loss through the wood studs) and less air leakage for a substantially higher Effective R Value.

Airtight Construction – A small number of sealed joints and precision manufacturing prevent drafts and heat loss. A typical SIP home will meet blower door tests between 0.5 ant 1.0 ACH.

The result? A building structure and envelope that is twice as strong and twice as energy efficient as a stick-framed home.

2. Engineered Modular Floor System

Precision-built floor systems are cut to exact lengths and designed for maximum span and minimum fuss.

Long Spans, No Load-Bearing Walls – Spans up to 24’ wide, giving you open-concept freedom and unlimited interior layout possibilities.

Easy Plumbing & Mechanical Runs – Open-web floor trusses make routing plumbing, HVAC, and wiring fast and simple.

Fast Installation – Modular floor sections can be assembled on site and craned into place with a boom truck and secured by a two-person crew in hours, not days.

3. The 4-Foot Grid Design Platform

Every Golden Age home is designed on a 4-foot grid, making every panel, floor cassette, and roof component modular and interchangeable.

Scalable Design – From additions and ADUs to three-storey apartments, this design system is scalable to many build forms.

Less Waste – Material usage is optimized for 8 x 24 panelized construction, reducing cut-offs, cost, and waste.

Perfect Alignment – Walls, floors, and roofs lock together seamlessly for superior structural and energy performance.

Build Speed - Repeatable patterns and sizes with minimal roof lines or other complex details means faster assembly.

Easily Customized. Inside and Out.

Exterior Finishing

-

Wrap the house with a vapour permeable house wrap. Add a 1/4” furring strip for drainage and ventilation. Apply siding on top of furring strips.

-

Wrap the house with a vapour permeable house wrap. Apply siding directly to house wrap as they are inherently “back ventilated”.

-

Wrap the house with a vapour permeable house wrap. Allow for a 1 inch gap between brick and SIP wall for drainage and ventilation. Anchor wall ties directly to the SIP.

-

Apply weather resistive barrier and drainage mat before the stucco base coat and finally the finish.

Foundation Types

-

Poured concrete or ICF basements are common for SIP construction. Install a capillary break (treated lumber and a sill seal) using anchor bolts before connecting the SIPs.

-

Same as Full Basement. Install a capillary break (treated lumber and a sill seal) using anchor bolts before connecting the SIPs.

-

Piles are a fast, affordable, and environmentally friendly way to build a SIP house foundation. Simply attach U or L brackets to the piles and use timbers to create your foundation.

-

Install a capillary break (treated lumber and a sill seal onto the slab using anchor bolts, and then set the SIP walls on top of the sill plate, securing them with fasteners and applying sealant/expanding foam to all joints for an airtight connection.

Interior Finishing

-

Using SIP roof panels means having conditioned attics by default. Use them to house mechanical, for personal storage, to add additional loft space, or enjoy a vaulted ceiling.

-

Our open web floor truss system eliminates the need for load bearing walls for spans of up to 24’. This provides nearly unlimited floor plan options, including open concept areas.

-

SIP walls are 100% OSB on the inside from floor to the top of the ceiling. This makes it fast and easy to install large format drywall since it doesn’t have to be cut to fit stud locations.

-

Open web floor trusses + conditioned attic spaces makes it fast and easy to run HVAC, electrical, and plumbing through the floor system.

What’s in a Golden Age kit?

Each Golden Age kit includes everything you need to build an enclosed building structure:

Complete SIP wall system

Complete SIP roof system

Prefab floor system (SIPs and/or trusses)

Structural LVL ridge beams

Pre-cut lumber and splines

Sealants, fasteners, and house wrap

Detailed assembly guides

Cost-Competitive by Design

SIPs have a higher upfront material cost than stick framing, but they lead to a lower total cost if the design, manufacturing, and assembly are aligned from the start. At Golden Age, every home kit is optimized for SIP construction: simple forms, clean rooflines, and precise dimensions. This alignment reduces fabrication time, minimizes waste, and speeds up on-site assembly—delivering beautiful, customizable, energy-efficient homes that rival or beat the cost of traditional stick builds.

We’re here to help.

We are more than just a manufacturer. Whether you’re looking for a custom home kit design or assistance during construction, the Golden Age team is here to help every step of the way.

-

We help you design from scratch or adapt existing plans to fit seamlessly with the Golden Age System™, ensuring beauty, efficiency, and performance.

-

Our team can assist with permitting, engineering reviews, and other regulatory approvals to keep your project moving smoothly.

-

We provide skilled assembly crews — or connect you with trusted partners — to quickly enclose your home using our modular system.

-

From technical documentation to on-site guidance, we equip your crews (or DIY builders) with the knowledge to assemble and seal homes properly.